Mechanical and environmental stresses require demanding performance capability from electrical interconnections. Industry is turning to manufacturers experienced in making MIL-SPEC interconnects for rugged and reliable solutions. Interoperability of MIL-SPEC interconnects for military and commercial markets is high, allows for cost savings, reduced maintenance cycles, and eases troubleshooting.

The Challenges Surrounding “Everyday” Commercial Applications

Commercial and industrial applications are increasingly facing extreme operating environments that exceed the limits of traditional specifications. These harsh environment applications require standards for connectors and cables that can meet these increased demands for reliability and ruggedness. Military organizations around the world have faced these types of challenges for decades and have formulated a wide range of connector and cable standards to ensure reliability in the most demanding of environments. Leveraging the military-grade technologies available from suppliers who design and manufacture for military applications can benefit commercial application and system integrators suffering from connector reliability and maintenance issues.

This article discusses the benefits that commercial and industrial manufacturers can harness by utilizing connector and cable technology developed for military applications but adapted to commercial applications.

MIL-SPEC in a Nutshell

Military specifications and standards (MIL-SPEC and MIL-STD) arose from the need to create a common platform for quality, interoperability, and traceability of components, devices, and systems across multiple military organizations. With rigorous quality standards, inspection protocols/methods, and the ability to trace failures to a root cause, the U.S. military has been able to rely on this technology, while interoperability specifications give flexibility to use component types that meet a specification across a variety of systems, without the need to re-engineer a component for every use.

The value of interoperability for both the military and commercial markets is extremely high, and allows for substantial cost savings, reduced maintenance cycles, rapid repairs, and eases troubleshooting/training. As the requirements for electrical interconnects are varied, there are a wide range of specifications and standards to ensure components are interoperable, mechanically rugged, resistant to environmental degradation, can operate over a wide temperature range, and maintain a caliber of quality, thus ensuring performance requirements are met under harsh operating conditions.

MIL-SPECs for connectors dictate everything, including the exact geometry and tolerance of each design feature, material used, material sourcing, manufacturing method, inspection and testing processes, mechanical and electrical performance, and traceability. There are also additional specifications that define certain interconnect characteristics, such as the environmental ruggedness of connector and cable jacket material and coatings, hermetic seals, mating force, and aspects of assembly.

How MIL-SPEC Connectors Can Be Adapted to Commercial Applications

Adapting MIL-SPEC interconnects for commercial and industrial functions is increasingly common. Applications within the aerospace, medical, instrumentation, oil and gas, downhole mining, and commercial unmanned vehicles (air, land and water) have successfully used MIL-SPEC-based products for several years. Using the MIL-SPEC interconnect design for non-military applications is advantageous for commercial companies as they are generally available and do not require new design time or testing to manufacture unless specific changes are needed.

The military qualification processes for electrical interconnect marginally increases the cost of a product, however the volume of product ordered by the military thereby decreases the cost of the tooling required to design and manufacture, therefore it may be much more cost-effective and reliable to leverage interconnect solutions from manufacturers with a legacy of building high-quality MIL-SPEC interconnects than manufacturers inexperienced with the rigors of building to such high quality standards.

Furthermore, some manufacturing processes and requirements for MIL-SPEC interconnect products can be adapted or streamlined for commercial and industrial applications – for example by utilizing the base MIL-SPEC product design but exchanging any controlled or hazardous materials for commercially safe alternatives. Utilizing commercially available high-quality materials that don’t require traceability, or foregoing additional inspection and qualification stages that aren’t necessary in ensuring the product meets high reliability and performance standards can prove beneficial for commercial companies. Industrial committees often start with SAE standards created for military applications, then modify and adapt them to meet the specific demands of their industry and modify requirements that are not application-critical.

Interconnect Solutions Based on MIL-SPEC and Built for Commercial/Industrial Apps

A wide range of MIL-SPEC style connectors and cable assemblies are currently used in commercial, industrial, and military applications. The following section will discuss several of these commonly-used connector types which have been derived from military standards and how they have been adapted into commercial applications, including high-density miniature connectors, hermetically sealed connectors, fiber optic connectors, circular connectors, twinax/triax connectors, and hybrid layouts.

Medical Equipment and Unmanned Vehicles

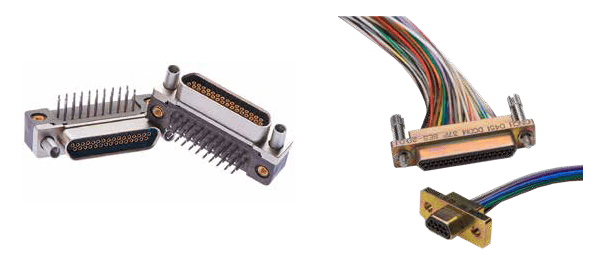

MIL-DTL-83513 is a military standard for micro-miniature D-shaped connectors, defining the specification for a variety of performance requirements. MIL-DTL-83513 parts are also referred to as “Micro-Ds” which are the half-size version of D-Subs, a product also adopted into the commercial market having originated as a military-specified product. These types of connectors are often used in aerospace, fire control systems, smart munitions, embedded computers, SIGNIT (Signal Intelligence) Sensors (RADAR, SONAR, LIDAR) amongst others. They are designed to be compact (0.025” pitch), low weight, and highly reliable under extreme vibration and shock conditions, and are also available in hermetically sealed and high-temperature versions.

Image 1: Dura-Con Micro-D Connectors.

Additionally, MIL-DTL-83513 connectors are often employed for use in rugged industrial, aerospace, space, medical equipment, unmanned vehicles, and robotics applications, due to their superior reliability and ruggedness. These uses include GPS and inertial navigation - utilized for all unmanned vehicles as well as RADAR and LIDAR sensor arrays - medical imaging equipment, downhole equipment, and portable machinery. Furthermore, the versatility and compact size of these Micro-D connectors led to their use in deep-sea exploration, geophysics research/exploration, helicopters, and engine control systems.

For a specific example of the commercial use of MIL-DTL-83513 connectors, we can look to the down hole drilling equipment used in the oil and gas industry. Sensory components near the tip of the apparatus used for down-hole drilling are connected via MIL-DTL-83513 interconnect cable assemblies to communications hardware in order to enable measurement while drilling (MWD). The result is enhanced situational awareness, leading to more efficient drilling and optimized well placement.

Another commercial example of MIL-DTL-83513 connectors solving cutting-edge technology challenges is their use in micro-surgery equipment. A desire to utilize these connectors resulted in the development of a plastic Micro-D connector housing, i.e. non-magnetic, rather than the standard metal, leading to a cost reduction of 30%-40%. As all medical advances are extremely price-driven, this custom commercial solution enabled the use of high quality and reliable connector technology without sacrificing reliability or performance.

Aerospace Applications

MIL-DTL-26500 specifies a miniature circular connector type designed to be particularly environmentally resistant for aerospace applications. Their ruggedness, compact size, and lightweight construction makes them ideal for extreme applications, including aerospace, general-purpose aircraft, missile systems, and aircraft engines. As this type of connector is commonly used in commercial aircraft applications, some of the MIL-DTL-26500 connectors are also compliant with Boeing BACC45 and BACC63 connector standards.

Image 2: Omega Circular Connectors.

The key features of these connectors are superior resistance to fluid ingress, vibration/shock tolerance, environmental sealing, and electrical shielding, hence, these connectors are used in Fuel Quantity Indicating System (FQIS) cable assemblies. These connectors typically come in a variety of shell and pin configurations to accommodate a wide range of interconnect applications, with some variants also featuring low profile shells and designs specifically for flex circuit, soldered wire, and custom board mount applications.

Industrial Applications

The MIL-DTL-83526 standard details the specifications for circular, hermaphroditic, fiber optic connectors, built for in-line mounted applications. This type of fiber optic connector uses the expanded beam method for mitigating fiber optic signals’ general susceptibility to degraded performance due to interfering particulates and other surface deposits. Expanded beam technology ensures a higher level of environmental ruggedness than traditional fiber optic connections by optically enlarging the beam surface from hundreds to thousands of times greater surface area. Nevertheless, this type of connector can be manufactured to accommodate field terminable and repairable construction with standard fiber optic termination tools and equipment.

Expanded beam fiber optic connectors are ideal for indoor and outdoor networking applications and can operate as single mode or multimode. As fiber optic interconnects are less interference-prone than standard conductor-based electrical interconnects, fiber optic cabling with MIL-DTL-83526 connectors is increasingly being used to provide rugged and reliable networking in not just military and aerospace; but industrial applications, renewable energy, broadcast and other commercial applications.

Commercial versions of the MIL-DTL-83526 Expanded Beam optical connector are used in industrial applications, specifically oil and gas, for display and communication systems on oil rigs, as well as surface to subsurface communications in mining operations. Furthermore, commercial variants of these connectors have also been used in mixing boards for stadium and concert applications to run interference free audio and video signals throughout a venue. Miniaturized versions of commercial 83256 connectors have also been applied in broadcast communications for events as part of patching systems.

Image 3: Fibreco Expanded Beam Fiber Optic Connectors.

Military Applications

>MIL-DTL-38999 connectors are specified as miniature circular structures designed for high density and environmental resistance. This connector type uses removable crimp and hermetic solder contacts and comes in a variety of quick-coupling methods, such as bayonet, threaded, and breech. Some 38999 connectors are specifically designed for high density printed circuit board (PCB) applications, where having a small but environmentally rugged connector is essential due to packaging space constraints.

Image 4: Mil-Aero C-RJFTV 38999 Connectors.

This type of connector is used in a wide range of military and industrial applications all over the world, where applications such as aircraft engines, electrical test equipment, commercial business aviation, and aerospace launch vehicles, demand positively aligned and bonded interconnect that eliminates contact alignment issues. MIL-DTL-38999 connector variations can be employed in heavy wind and high moisture environments, as well as in applications which benefit from fast disconnect coupling.

Heavy Machinery

There are many other examples of military-style connectors used in commercial applications - for instance MIL-DTL-26482 specify circular electrical connectors that are environmentally resistant. These types of connectors are commonly used in commercial applications such as renewable energy (land and sea wind farms), robotic automation, and rail. Specifically, commercialized versions of these connectors have been used in the oil and gas industries, industrial robotics, automation, machine tool applications, transportation equipment including trains, planes, buses, and trucks, and as power and signal connectors for heavy machinery applications, such as heavy construction equipment and rail systems.

MIL-DTL-26482 style connectors have variants designed for extreme environment and high pressure/vacuum applications, perfect for use in commercial aerospace. Commercial/industrial uses include a metallic shell connector used for Ethernet data communications in harsh environments, which is further compatible with IEC 60603-7-7.

Image 5: Mil-Aero MIL-DTL-26482 Connector.

Variants of the 26482 connectors have been used as power and signal connectors for heavy machinery applications, such as heavy construction equipment and rail systems. There are also a wide range of oil and gas and commercial aerospace uses for 26482 connectors.

Reliable Solutions for Commercial Applications

In a wide range of commercial and industrial applications, the mechanical and environmental stresses require demanding performance capability from electrical interconnect. This is increasingly the case as mechanical actuators and sensors are replaced, or augmented, by electrical systems. With limited support from common standards, these industries are turning to connector and cable manufacturers experienced in making MIL-SPEC interconnects to provide rugged and reliable solutions. This trend is on the rise, and will likely continue as electrical control, actuation, and sensing becomes broadly adopted.

M83513/01-GC

M83513/01-GC

M83513/20-G01NN

M83513/20-G01NN