CIN::APSE®

Our industry leading solderless compression connector technology provides high density and high speed solutions for a wide range of custom applications.

Search Products

How CIN::APSE® Works

Connection

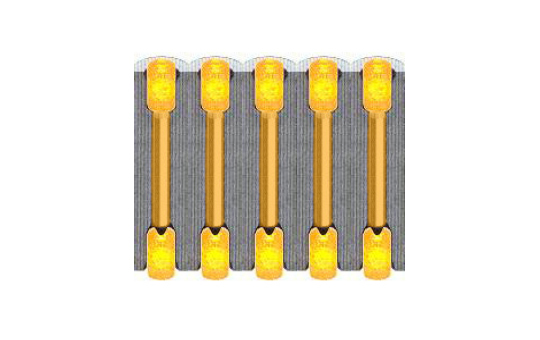

The connectors are constructed by two main components, insulating housing and an electrically conducting contact. The liquid crystal polymer insulators are molded and the contacts are a bundled gold-plated molybdenum wire. Gold plated copper spacers are used for long Z-axis connectors.

Connection

The connectors are constructed by two main components, insulating housing and an electrically conducting contact. The liquid crystal polymer insulators are molded and the contacts are a bundled gold-plated molybdenum wire. Gold plated copper spacers are used for long Z-axis connectors.

Positioning

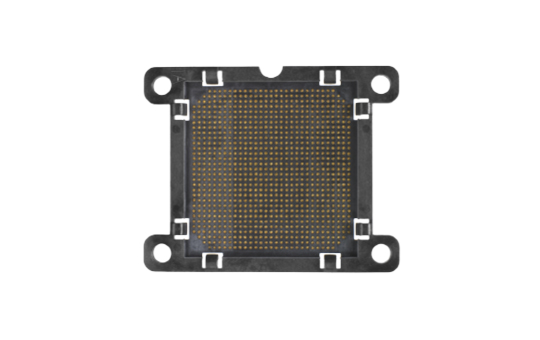

The positioning is designed into the insulating housing. Insulation housing are molded for high volume and machined for prototypes.

Positioning

The positioning is designed into the insulating housing. Insulation housing are molded for high volume and machined for prototypes.

Mounting

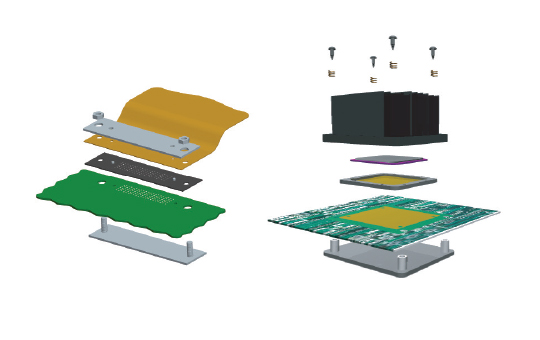

The connectors are positioned and mounted between boards and components using generally available alignment and compression hardware. Hardware can be press fit into PCB or utilized with a bolster plate for maintaining even compression across a large socket. Designers recommend PCB layout for gold plated pads and alignment holes locations.

Mounting

The connectors are positioned and mounted between boards and components using generally available alignment and compression hardware. Hardware can be press fit into PCB or utilized with a bolster plate for maintaining even compression across a large socket. Designers recommend PCB layout for gold plated pads and alignment holes locations.

Product Overview

It takes more than an ordinary connector to support advanced performance interconnect applications. CIN::APSE® is a proven solderless Z-axis connector technology that offers exceptional mechanical and electrical performance at signals well above 50GHz.

Stacking Connectors

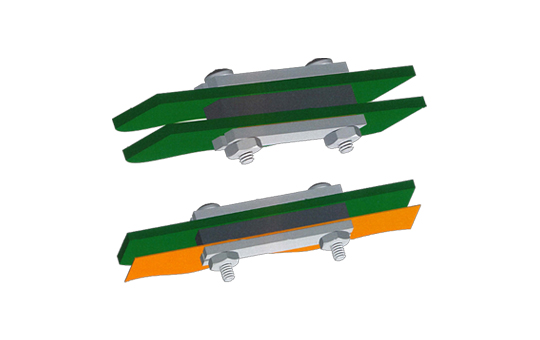

Stacking connectors for connecting PCB or flex, PCB to PCB or component to PCB without the use of solder.

View Products

Stacking Connector Hardware

Hardware that has been designed to maintain uniform compressive force across all contacts.

View Products

Stacking Connector Jumpers and Assemblies

Short flex PCB assemblies for coplanar and right angle board-board connections.

View Products

View Brochure

Applications

The CIN::APSE solderless compression connector technology is the most widely implemented crimples and solderless high speed interconnect system for key industries including Commercial Aerospace, Space, Defense, Test & Measurement. Examples of the applications include:

Geostationary Communication Platforms

Geostationary Communication Platforms

Inertial Navigation Systems

Inertial Navigation Systems

Network Switches

Network Switches

CPU and ASIC-to-board Connections

CPU and ASIC-to-board Connections

Key Features

- Maximize SWaP (Size, Weight, and Performance) for space and weight constrained designs

- Pitch grid of 2.00 mm, 1.0 mm and 0.80 mm achievable

- Thin profiles from 0.020" and greater

- 2-piece design reduces additional space and weight

Solderless

Solderless

- Compression sufficient for establishes multiple points of contact, RoHS compatible

- No thermal processing or X-ray inspection required

- Reversible mating process for multiple cycles

Customizable

Customizable

- Design team available for mechanical drawings and product sketches

- Prototypes available for low quantities

- Profile thicknesses from 0.020" to 1.0"

- 2 to 7,356 contacts have been used per connector, but no limit exists

- IC-to-PCB, PCB-to-PCB, Flex-to-PCB, Component-to-PCB

Reliable

Reliable

- Excellent shock and vibration stability, 100 Gs shock, 20 Gs vibration

- Thermally stable, life and cycle testing, 5,000 hrs @ 170°C

- Electrically stable, > 1,000 MΩ @ 500 VDC