When designing a product for harsh environments and markets, such as military, aerospace and heavy industry, design engineers can feel restricted in what products and procedures they can use in order for the final product to match requirements.

Designing for Harsh Environments with Pluggable Transceivers

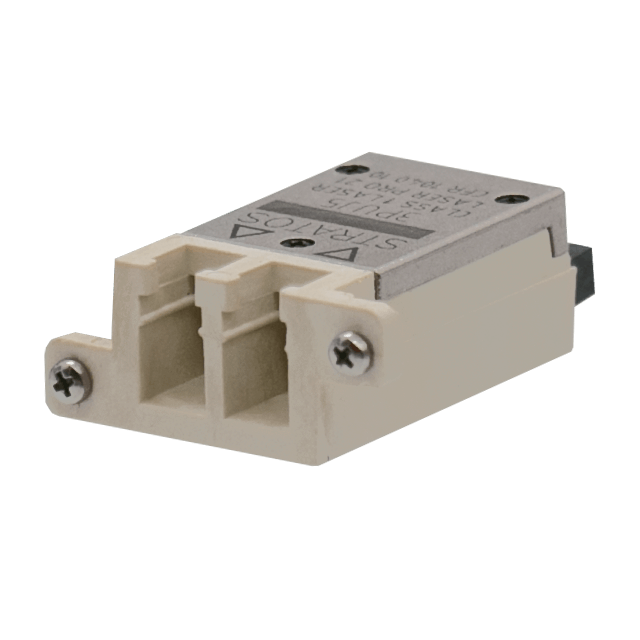

Building on the proven performance of Cinch’s Low Rider family, Cinch has created a Front Load Pluggable transceiver family (FNx) to help fill the gap experienced by engineers. Our pluggable transceiver has a small foot print, high performance and excellent environmental characteristics, while at the same time, offering the flexibility and convenience of a pluggable product. And at half the size of a standard SFP, the FNx also allows designers more room on the application card.

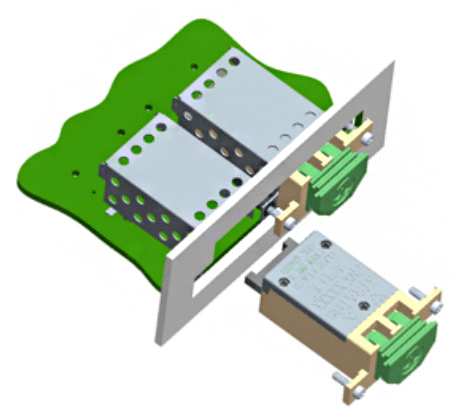

Figure 1: An overview and size comparison between a traditional SFP and the FNx.

Enhancing Pluggable Transceiver Reliability

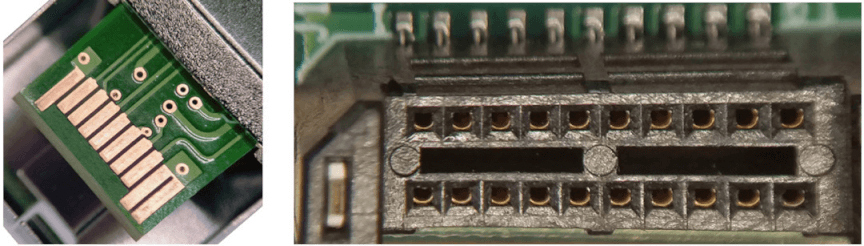

The main reason for pluggable transceivers not being used in rugged applications, is that the traditional boardedge contact is inherently sensitive to vibration and shock. In Cinch’s FNx series of transceivers, true pin/socket contacts are used as part of the solution to this problem. Below in figure 2, a side by side comparison is made between these two different contact types, to show the difference. Both the pin and socket contact is plated with 50 µ-in of gold, guaranteeing performance over hundreds of mate/demate cycles and extending the life of the product.

A second area of concern for traditional pluggable transceivers is the bail latch used. Cinch’s FNx series utilizes captive screws to fasten the transceiver to the cage, meaning a much more secure hold than the bail latch.

Users may prefer or need a SM or MM source for various reasons, such as performance, transmission length and existing hardware. Many times the transceiver used is the one thing that limits a product to being SM or MM. Having the option to change out SM/MM, would open doors for multiple uses of the same hardware, and enable a product capable of interfacing with existing systems, or for future upgrades in the field.

Figure 2: Comparison between a traditional card edge connector and the pin/socket solution used in the FNx. The latter provides superior performance, especially over temperature and vibration.

It’s not only the change between SM and MM that can be beneficial. Allowing the same platform to be used for a variety of communication speeds, further cements the pluggable transceiver as a practical and convenient option. From a manufacturers standpoint, a pluggable transceiver allows late configuration, and a singular design to fulfill multiple needs.

Additionally, optical transceivers are often sensitive to high temperature manufacturing processes, such as reflow ovens, but a pluggable design allows the transceiver to be added after the high temperature processing has completed, thereby simplifying the overall assembly process.

| Features | Benefits |

|---|---|

| Small footprint | Half the size of a traditional SFP, more room on the application card. |

| Rugged, I-temp | Specifically targeted to Mil-Aero and rugged Industrial market -40°C - +85°C. |

| Pluggable | Allows late configuration and ease of field changes from MM to SM or to different data rates. |

| True Pin/Socket | Provides superior vibration and temperature performance compared to traditional card edge connectors. |

| Gold contacts | Uses 50 µ-inches of gold plating on the pin and socket for high reliability lifetime use. |

| Captive Screw | Captive hardware secures the transceiver module in the cage over vibration, as op-posed to traditional SFP which uses a single point of contact bail latch. |

| MM and SM | Same application card foot print, simply change transceiver module. |

| Data rates | Current family offering is 100M and 1G. Future modules are planned for 2G, 4G, and 10G. |

Table 1: Some of the most interesting features of the FNx product family are listed below, together with a brief overview of the advantages gained.

Flexibility and Durability: The Benefits of Pluggable Transceivers

With the release of Cinch’s family of Front Load Pluggable transceivers, there is an option for designers to use a pluggable transceiver, even if their product is to be used in harsh environment. The use of a pluggable transceiver will add value to both manufacturer and customer, by offering flexibility during the assembly process and end use.

Figure 3: Front load pluggable transceiver.

Explore the unmatched flexibility and durability of Cinch's pluggable transceivers for harsh environments.

Optical Technology

Optical Technology

Pluggable Transceivers

Pluggable Transceivers