The need for high-speed data communications is increasing, even in remote areas that are hard to reach and work in. This often involves some very hazardous and often explosive atmospheres, including oil, gas, coal, and deep-sea platforms. Bringing IT (information technology) and OT (operational technology) to heavy industry and volatile environments can be done safely and reliably with ATEX-approved fiber optics.

Connectivity Considerations for Hazardous Environments

As the only manufacturer to offer an expanded-beam optical connector that is ATEX-approved, Cinch Connectivity Solutions understands the challenges involved. This article provides a deeper dive into those challenges and explains why overcoming them is worth the effort.

The need for high-speed data communications is increasing, even in remote areas that are hard to reach and work in. This often involves some very hazardous and often explosive atmospheres. The ‘giants’ here remain oil, gas and coal, through surface and underground mining, and deep-sea platforms. Combining these heavy-industry and hazardous environments with technologies more at home in a data center is not simple but it is becoming more important to bring the IT (information technology) and OT (operational technology) closer together.

Electrical equipment can be an obvious ignition source in an explosive environment, which introduces further design requirements. Developing interconnects that can operate in explosive atmospheres also means withstanding extreme temperatures, humidity, vibration, shock and physical stress.

The use of fiber optics is also increasing in these applications, due to the demand for higher bandwidth and lower latencies. However, right now, the majority of optical interconnects are based on physical contact, mainly because it is the most common type of optical interconnect available. That does not make the best, though. In terms of ease of use and rugged flexibility, expanded beam technology is far superior. The Fibreco Geo-Beam™ EX product line from Cinch Connectivity Solutions has been approved for use in ATEX Zones 1 and 2, and even in Zone 0 when used with the appropriate hardware.

Understanding ATEX Standards for Explosive Atmospheres

It is important to appreciate that an explosive atmosphere, or ATEX, is not restricted to the presence of obvious flammable substances, such as gas or oil. In the not-so-distant past, flour mill explosions were unfortunately commonplace. The same conditions exist today, wherever fine particles of combustible dust are allowed to circulate and mix with air. Safety regulations are in place to protect workers wherever these conditions may exist, which includes preventing the release of combustible substances, along with controlling the use of potential sources of ignition.

With no exposable electrical interconnects, fiber optic technology may appear to be an obvious choice to providing high-speed connectivity in ATEX environments. Using light to provide data communications does not require an electrical current to flow, removing one obvious source of ignition.

This is why standards exist, to control the use of technologies that may constitute a form of ignition. The main approvals to look for are ATEX and IECEx, these are typically provided in the form of ATEX Certification, an ATEX Quality Assurance Notification, and an IECEx Quality Assessment Report.

Communication Challenges in Explosive Atmospheres

Despite having no electrical sources, fiber optic interconnect is not deemed to be intrinsically safe. This means its use in an explosive atmosphere needs to be covered by standards intended to remove the risk of incident.

There are four main risks that exist, these can be summarized as:

- Optical radiation absorption raising surface temperatures - Wherein light escaping from the fiber optic is absorbed by materials, causing the surface temperature to increase. If the surface temperature reaches the ignition temperature of the surrounding area, it could lead to combustion

- Optical radiation absorption by combustible materials - If the wavelength of the light escaping coincides with the absorption band of the combustible material, its temperature will increase and may reach ignition temperature

- Wavelength reacting with oxygen - If the wavelength used reacts with oxygen molecules in the local atmosphere it could result in an oxidant, which represents one of the three critical conditions needed for combustion

- Direct interaction with explosive gas - The light could also interact directly with an explosive gas, generating either a plasma or a shock wave, both of which are a source of ignition

IEC 60079-28 Protecting Equipment that Uses Optical Radiation

The IEC standard IEC 60079-28 relates specifically to optical radiation in explosive environments. It is used across the world, and it defines a number of ignition sources, along with the protection required for equipment operating in various environments. This allows the safety process to quantified. Each parameter is given an identifying number or letter which can be used in the part number or specification for a component, such as a connector. There are three types of protection defined that relate to the use of a source of optical radiation in an explosive atmosphere, which are commonly referred to as Ex (referencing explosive) and op (referencing optical protection).

The two-letter references for each are commonly used as part of the component’s nomenclature, as follows:

- Ex op is - ‘is’ refers to ‘inherently safe’. This is used when the amount of optical energy is limited when measured in terms of mW/mm2

- Ex op pr - ‘pr’ refers to ‘protected’. The protection in this case is physical

- Ex op sh - ‘sh’ refers to ‘interlock’. This prevents ignition by interrupting the optical transmission

The Benefits of Fiber Optics in ATEX

There are numerous benefits of using fiber optic communications in favor of copper, which apply to many application areas. These include weight; fiber is much lighter than copper and as demand for bandwidth goes up, the point at which fiber becomes the better choice comes closer. It is becoming increasingly common to use interconnects that combine both copper and fiber in the same connector, often to provide both power and data. This is another key feature of the Geo-Beam EX, as it can accommodate hybrid inserts that combines optical, power and signal connections in the same explosion-proof housing. As the cost of fiber continues to fall and the need for higher bandwidth continues to climb, the convergence may see copper being relegated to just providing power.

Another important and related feature of fiber is its immunity to EMI. Fiber is not affected by electromagnetic emissions in the way copper is, even shielded copper. Also, it gives off no EM radiation, meaning it does not interfere with neighboring copper interconnects. This can be particularly important in applications that include the use of heavy machinery, where disruptions caused by EMI could result in catastrophic failure.

Simplifying Fiber Connections with Expanded Beams

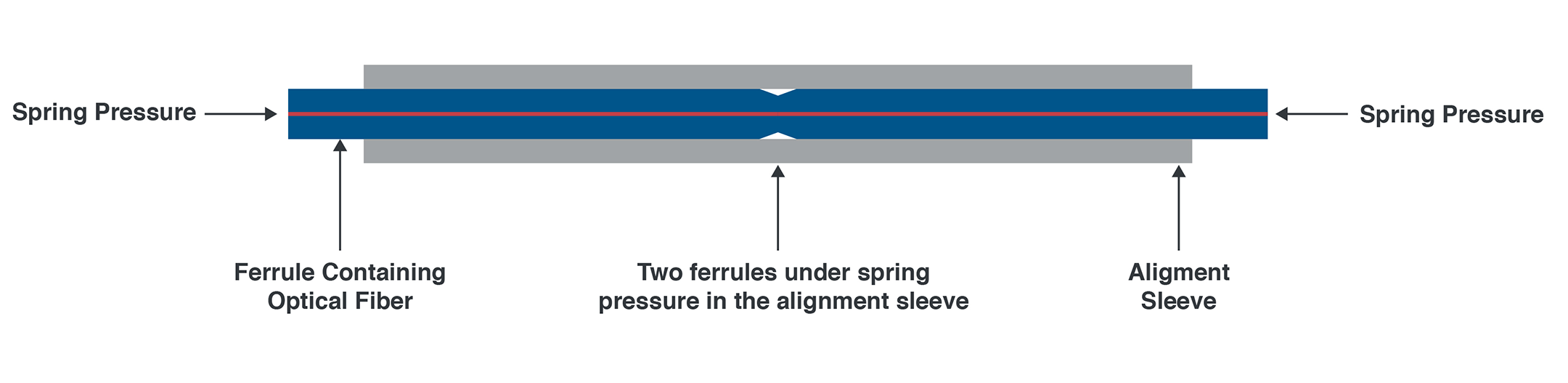

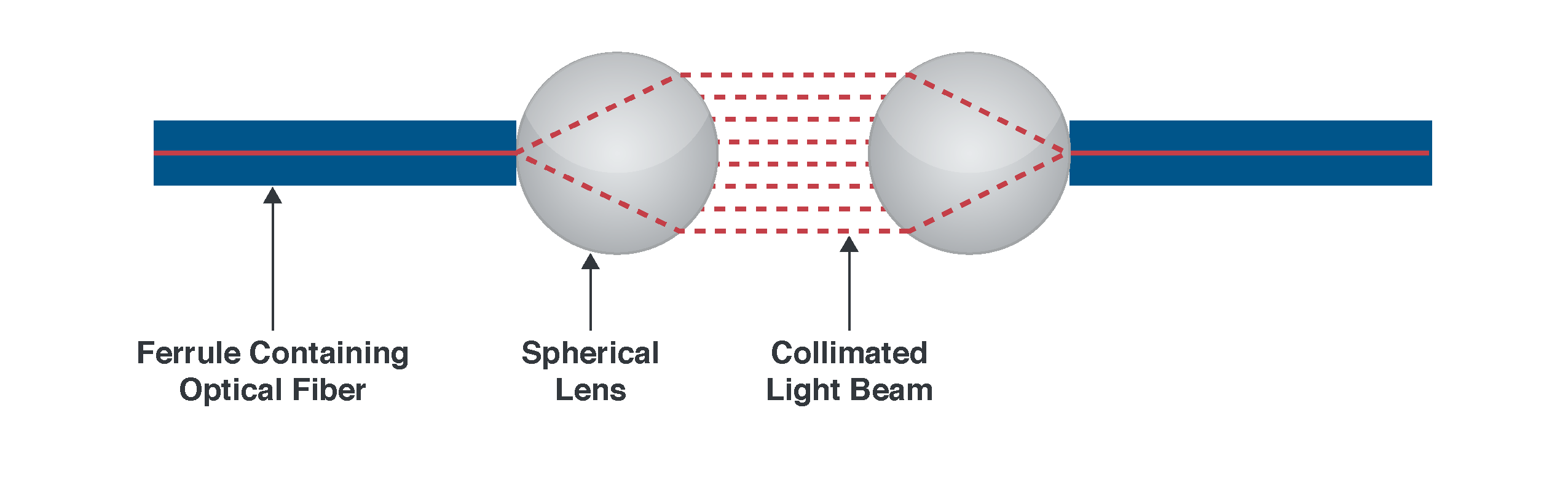

Connecting fiber optic cables in the field is also becoming simpler, thanks to developments such as expanded beam connectors. The most commonly used form of connection between two optical fibers is known as physical contact connection, also known as physical connection. A physical connection relies on the two ends of the fiber being perfectly aligned so that when they touch little or no light escapes, referred to as the insertion loss. However, physical connections are prone to wear, as well as SNR degradation due to dust or other particles finding their way in between the two ends. Expanded beam technology overcomes this, as it does not rely on a direct or physical connection. Instead, it uses lenses to expand and collimate the beam, which passes through an air gap between the two ends. A similar lens is used on both sides of the connection, but there is no need for them to physically touch. This makes connections simpler and less prone to wear.

Figure 1: Physical Contact Technology

Figure 2: Expanded Beam Technology

Expanded beam fiber optic connectors utilize a lens to expand and collimate the light emitting from an optical fiber. This collimated light beam is transmitted through an air gap to a mating connector, where the light is collected and focussed by a second lens into a second optical fiber to complete the connection.

Safety Certification for Fiber Optic Connections

The EU Directive 2014/34/EU (based on Directives 99/92/EC and 94/9/EC), which is commonly referred to as the ATEX Directive, and the IEC standard IEC 60079-28:2015 are used extensively within the industry. This is particularly relevant for manufacturers offering products for use in an explosive atmosphere.

The ATEX directive uses zones to classify the potential for explosion in a given environment. For example, Zone 1 and Zone 2 both relate to an explosive atmosphere formed by the presence of the key elements needed for an explosion. These are a flammable substance (such as a gas, vapor or mist), coupled with an oxidizer and a source of ignition. If these conditions are likely to occur on a day-to-day basis the area would be classified as Zone 1, while if the conditions are not likely but could occur it would be classified as Zone 2. An area where an explosive mixture is always present or is present for long periods of time would be classified as Zone 0.

As explained, the Geo-Beam™ EX series of explosion proof expanded beam connectors from Cinch Connectivity Solutions has been designed for use in hazardous environments and allows power, data and optical connectivity to be consolidated into a single connection. As such, it is supported with optical inserts that can support 2, 4, 6 and 8 expanded beam optical channels, as well as hybrid inserts that can support 4 expanded beam optical channels and 2 non-optical channels, or 2 expanded beam channels and 4 non-optical channels. This includes using mixed-optical-mode connections within the same insert.

Operating Safely in Hazardous Zones and Explosive Environments

The series has been designed for use in Zone 1 and Zone 2 hazardous areas, but when combined with the appropriate hardware they can also be used in a Zone 0 hazardous area. This makes them ideal for applications such as oil, gas and offshore drilling, petrochemical refineries, chemical manufacturing plants and pharmaceutical manufacturing.

The inline plug and box mount bulkhead are manufactured from stainless steel. The connector uses a tri-start trapezoidal coupling method with reduced turn and additional locking. This gives the reassurance of an audible click when fully engaged to indicate positive mating. The connectors can be used in upstream, midstream and downstream applications and comply with both ATEX and IECEx standards, covering Europe and the rest of the world, respectively.

This means the Geo-Beam™ EX series is used in explosive and hazardous environments around the world, including drilling (oil, gas, offshore), petrochemical refineries, chemical manufacturing plants and the pharmaceutical industry. The connectors offer a typical insertion loss of -1.5 dB for single-mode and -1.0 dB for multi-mode connectors. The return loss is typically 40 dB in single-mode and they are rated to IP67.

The Future of Fiber Optics in Hazardous Environments

The use of fiber optic connectivity is moving out of controlled environments, like data centers, and into heavy-industry areas such as mining and petrochemical manufacturing. These are hazardous areas where the conditions for explosive episodes can occur.

The engineering community recognizes both the need, and the challenges involved with using fiber optics in an explosive environment. Through the combined efforts of leaders in their fields, the industry has developed standards that ensure the safe operation of fiber optics in explosive atmospheres.

Cinch Connectivity Solutions is one such leader. It has many years of experience and a broad portfolio of qualified parts that are used in the most challenging applications. The Geo-Beam™ EX series is certified to both the ATEX Directive 2014/34/EU and IEC 60079 specification, providing a robust and reliable way of bringing the benefits of fiber optics to applications operating in explosive atmospheres.

Explore Cinch's full range of Geo-Beam™ EX Expanded Beam Connectors.

Geo-Beam EX Expanded Beam Connectors

Geo-Beam EX Expanded Beam Connectors